Rent

ProLift offers daily, weekly, and monthly rentals. Find the right equipment for maximum productivity and safety.

Let us know how we can assist you! A ProLift specialist will connect with you to help with your material handling needs.

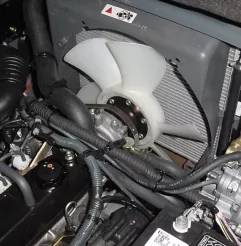

Forklift alarms and strobe lights are essential for enhancing workplace safety by alerting employees to forklift activity. Explore how these features can reduce accidents, improve awareness, and create a safer environment for everyone in your facility.

A stealthy forklift is a quiet machine lacking the warning safety devices common in other forklifts, such as flashing beacon lights or backup alarms. In a mixed fleet, you might find some forklifts equipped with flashing lights, others with alarms, some with both, and others with neither.

Without these alerts, pedestrians rely on visual cues or sound to notice forklifts nearby. When a stealthy forklift approaches, it may be too late for pedestrians to react safely by the time they realize it’s there.

By law or standard, OSHA does not require a flashing beacon, back-up alarm or even a fire extinguisher on every forklift. Warning safety devices are considered a demand of the environment in which the equipment operates. If an environment is loud, compliance officers may suggest flashing beacon lights; however, if a facility has many blind spots, a back-up alarm is a better solution. It is important to note while these devices are not required, any safety options installed on the forklift must be in working condition.

When an OSHA compliance officer makes decisions, they may consider local concerns and regulations as well personal interpretation of the law. To meet a violation of the General Duty Clause, an employer does not have to break a specific law or standard. This clause requires employers to provide a safe work environment free from known hazards.

An OSHA compliance officer may note forklift fleet standards as the reason an alarm or strobe light would be required on a forklift.

If other forklifts in the facility are equipped with safety devices and one is not, upgrades must be made to standardize the fleet. Or, if the compliance officer feels strongly the working environment requires more precautions, they may include an alarm or strobe light as a requirement.

Consider the work environment and existing forklifts when deciding to use safety devices. They will protect your warehouse, product and more importantly, your employees.

Looking for a forklift part? Check out the MyToyota online parts catalog or reach out to ProLift to connect with one of our parts specialists for assistance.

ProLift is your one-stop shop for dock and door, forklift, and industrial battery maintenance. Contact us today to be connected with a sales consultant.

Let us know how we can assist you! A ProLift specialist will connect with you to help with your material handling needs.